| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Lipu

Model Number : 3600×7000

Certification : ISO9001:2008,CE,IQNet

Place of Origin : China

MOQ : 1set

Price : negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 30 sets/quarter

Delivery Time : 15-20 days

Packaging Details : Container

Product Name : Cement Ball Mill Equipment

Model : 3600×7000

Color : According to customer

Condition : New

Application : Cement Plant

Effective volume : 66.6m3

Capacity : 61-113t/h

Power : 1600kw

Weight : 245t

Rotary speed : 17rpm

Continuous Operation Cement Ball Mill Equipment , Ball Grinding Mill Machine

Introduction of Cement Mill:

Cement Mill is main equipment for grinding raw material and clinker in cement plant, used in individual grinding system and closed circuit grinding system combined with powder concentrator. It is also used in grinding middle hardness materials in metallurgical, electricity, chemical industry and other grinding materials.

Features of Cement Mill:

1. Large application range, simple structure and convenient maintenance;

2. Large capacity and continuous operation;

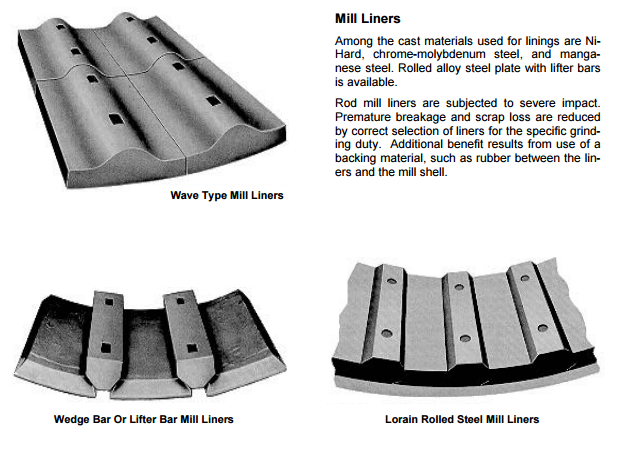

3. Barrel lining and grinding media can apply various abrasive materials;

4. Installation and adjustment are very convenient and easy to be operated.

Working Principle of Cement Mill:

The Cement mill is a horizontal cylinder rotating device driven by gears with two silos. The materials get into the first silo through the feeding quill shaft from the feeding device spirally and evenly. There are ladder lining board and corrugated lining board in the first silo loaded with steel balls of different sizes. The centrifugal force produced by the rotation of the cylinder raises the steel balls to a certain height which then fall down, thus making thumping and abrading to the materials. After the coarse grinding in the first silo, the materials get into the second silo through the monolayer partition panel with flat lining board embedded with steel sections for further crushing. The powder of the materials will be discharged from the unloading board to finish the grinding work.

Technical Data of Cement Ball Mill:

| Model

| Effective volume (m3) |

Max. steel ball load (t) | Capacity (t/h) | Power (kw) |

Rotary speed(rpm) | Weight (t) | ||||

| MQG | MQY | MQS | MQG | MQY | MQS | |||||

| φ3600×7000 | 66.6 | 93 | 116 | 139 | 61-113 | 121-225 | 140-260 | 1600 | 17 | 245 |

The Machine Spare Parts:

Product Picture Show:

|

|

Continuous Operation Cement Ball Mill Equipment , Ball Grinding Mill Machine Images |